Through our state-of-the-art technology and advanced materials, AFORGE’s Engineering and Advanced Manufacturing resolves longstanding and emerging challenges faced by small arms manufacturers.

We dramatically reduce design-to-production timelines, enabling rapid prototyping and quicker testing of new weapon designs and modifications.

Our USA production facilities enable on-demand production of replacement parts, minimize downtime, and reduce/eliminate dependence on global supply chains.

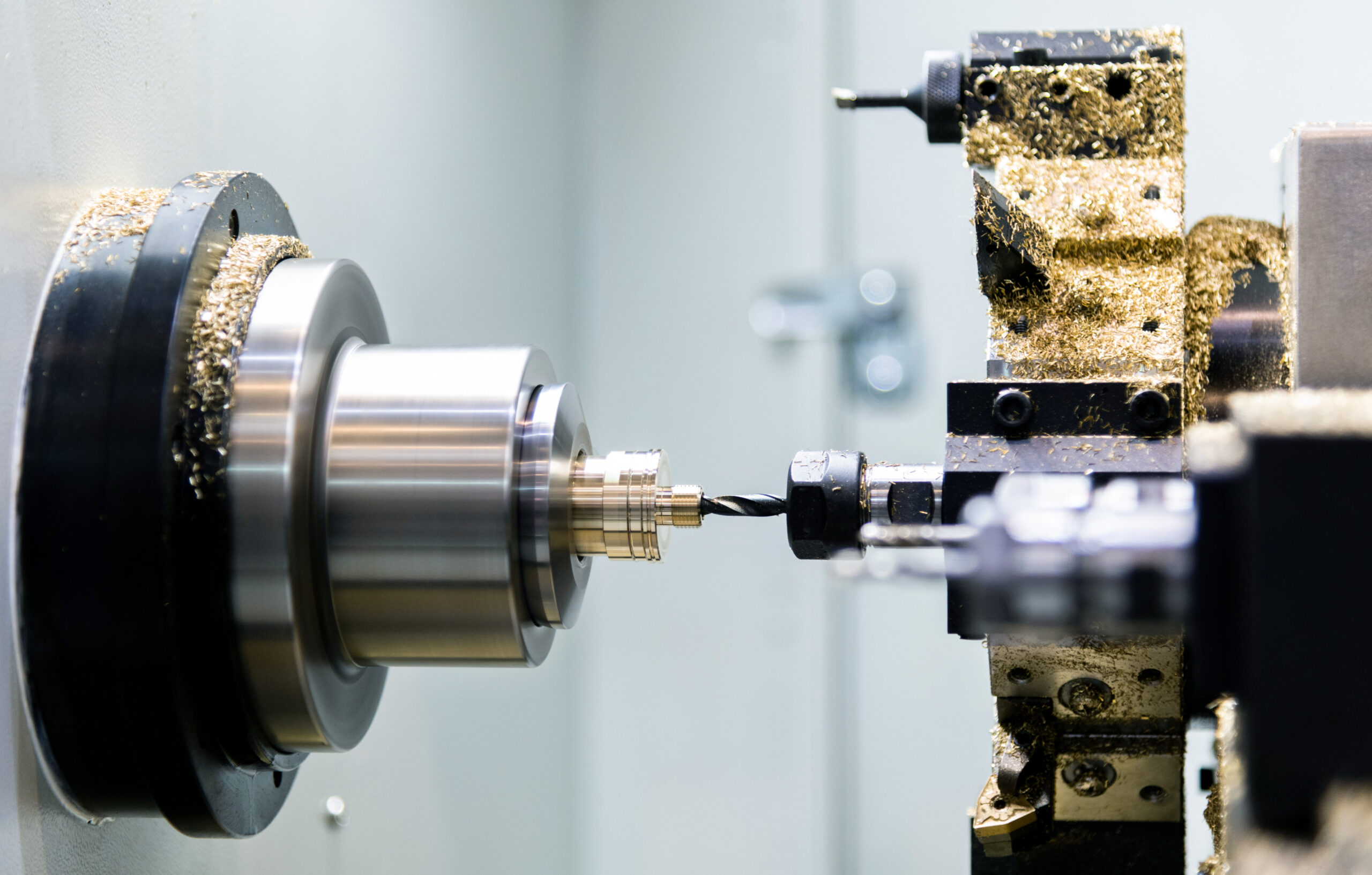

We are your obsolete parts solution provider. Our rapid reverse engineering and production of damaged parts or legacy components allows you to extend the service life of older weapon platforms.

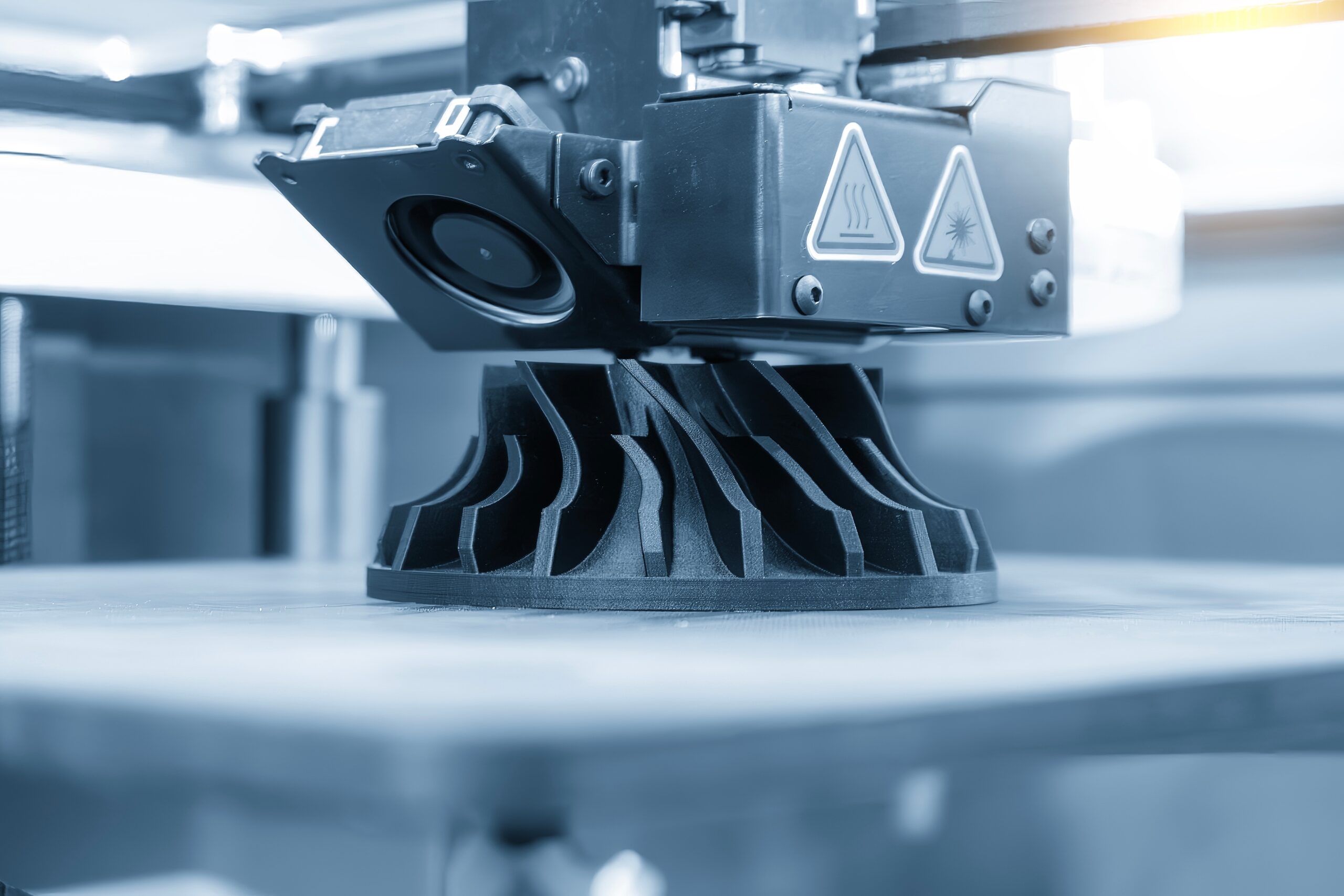

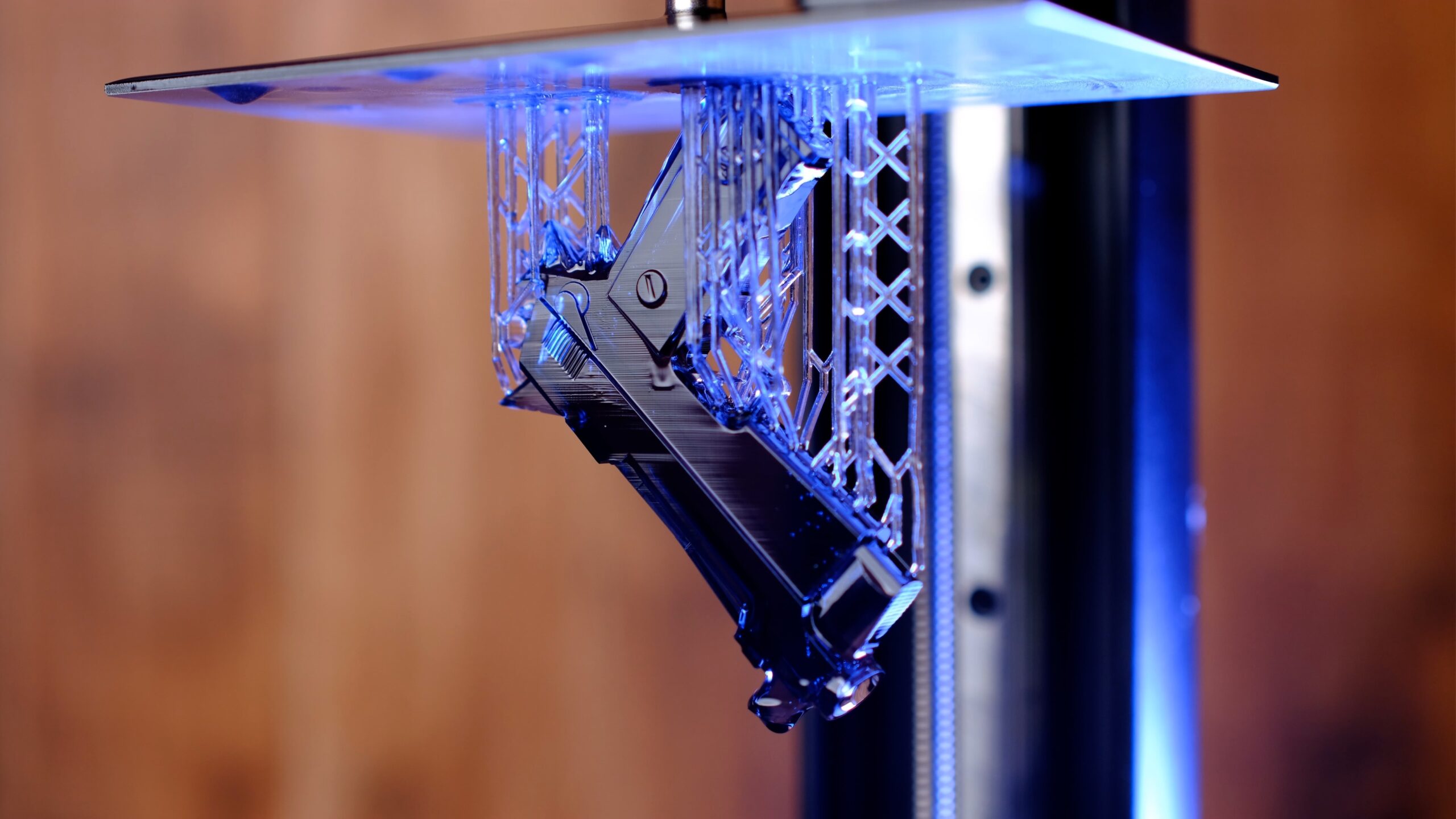

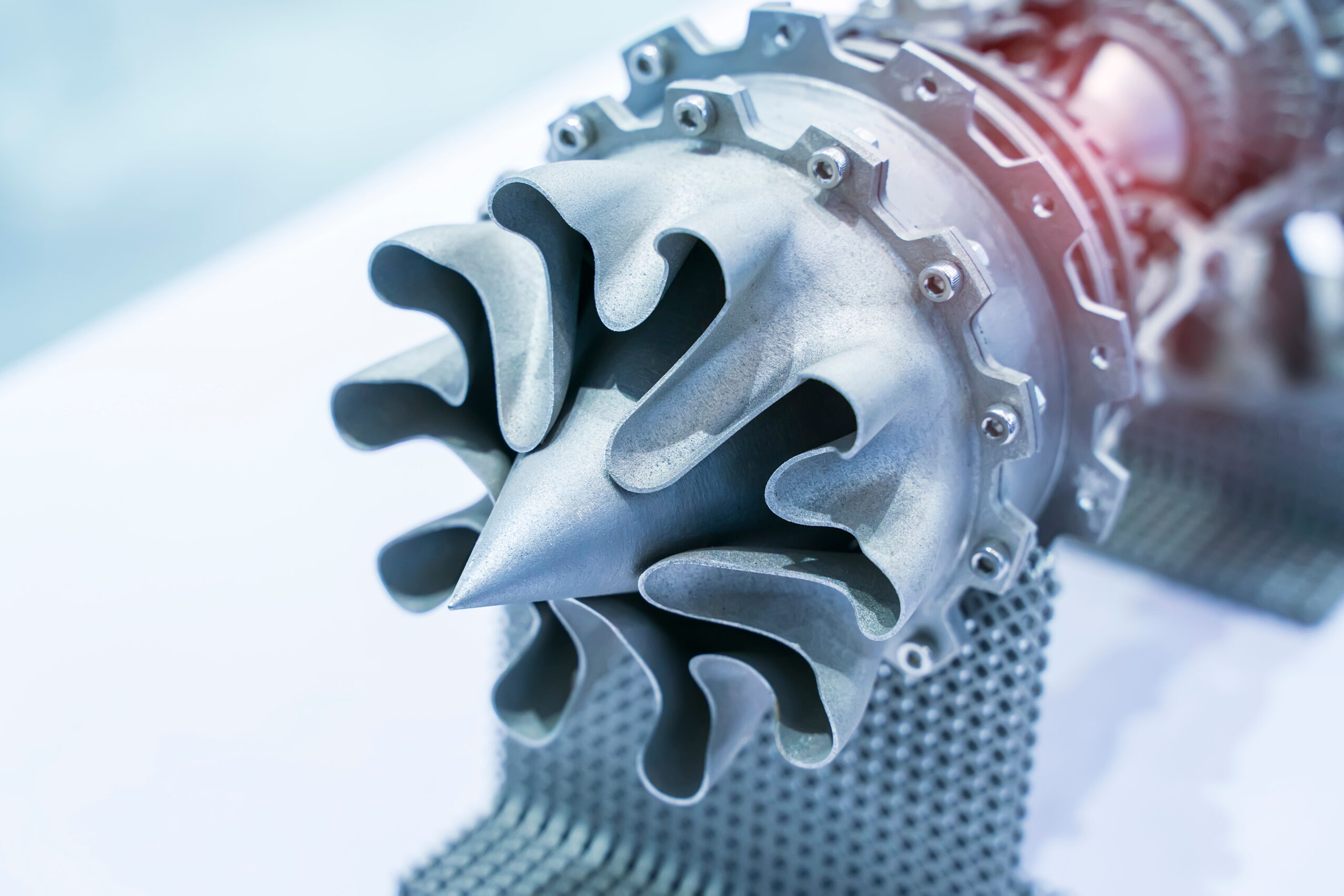

With additive manufacturing, we can create complex geometries and lightweight structures that are difficult, if not impossible, with traditional methods. This enables improved weapon ergonomics, reduced weight, and the integration of novel features for better performance.

AFORGE supports our clients in producing tailored solutions for specific user groups or mission requirements in customized runs of single-unit prototypes to scalable, repeatable, cost-effective production runs.

Client getting us examples or we will add this section later

Produce high-quality precision products with short lead times in mission critical environments.

AFORGE AM incorporates a range of innovative techniques such as automation, robotics, additive manufacturing (3D printing), artificial intelligence, internet of things (IoT), and data analytics paired with decades of in-theater experience for fast results at the speed of relevance.

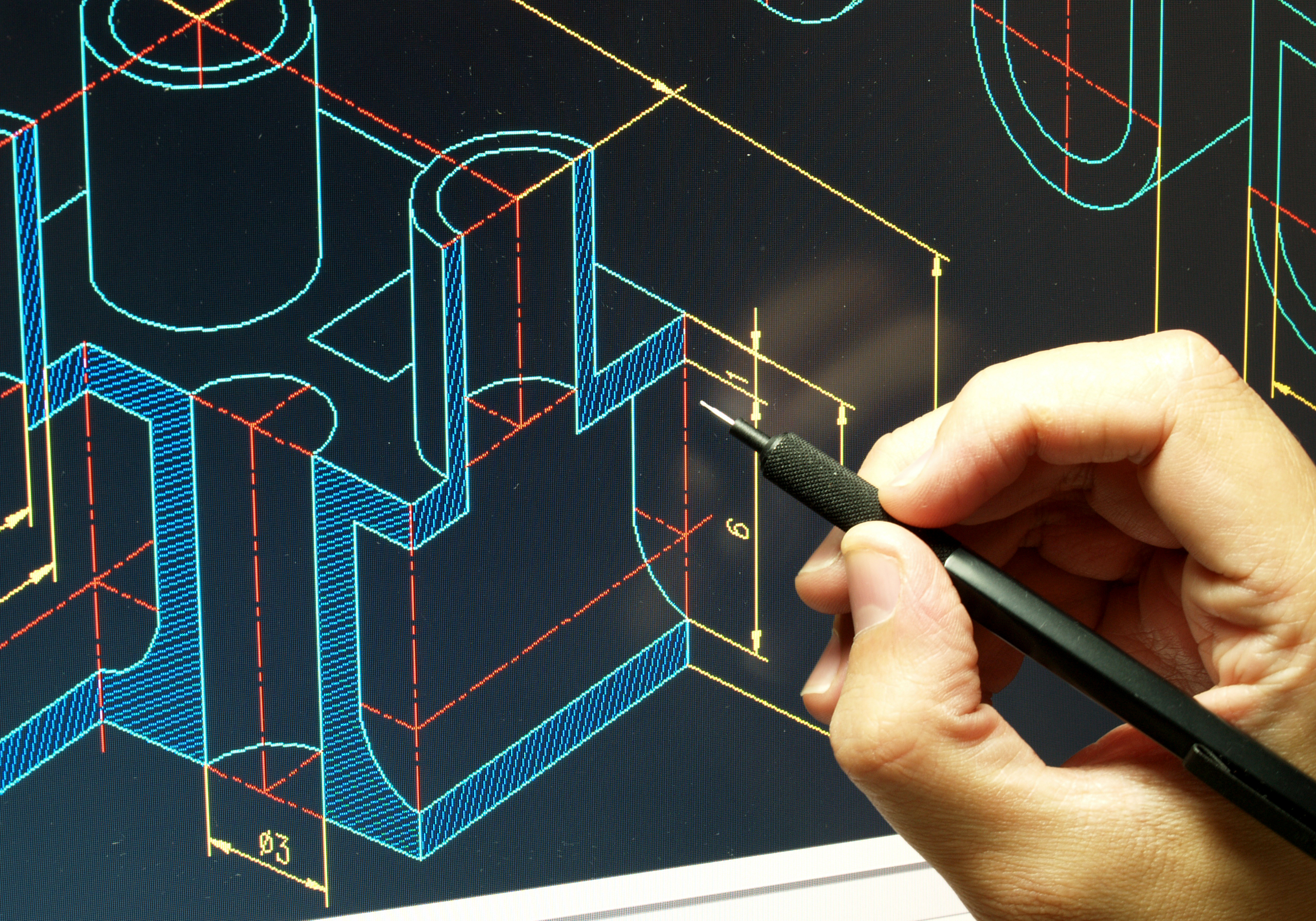

Design / Engineering Services

Advanced Manufacturing

Supportive Manufacturing Processes