Through our state-of-the-art technology and advanced materials, AFORGE’s Engineering and Advanced Manufacturing addresses key challenges faced by food and beverage OEM equipment manufacturers by offering solutions that traditional manufacturing methods struggle to provide.

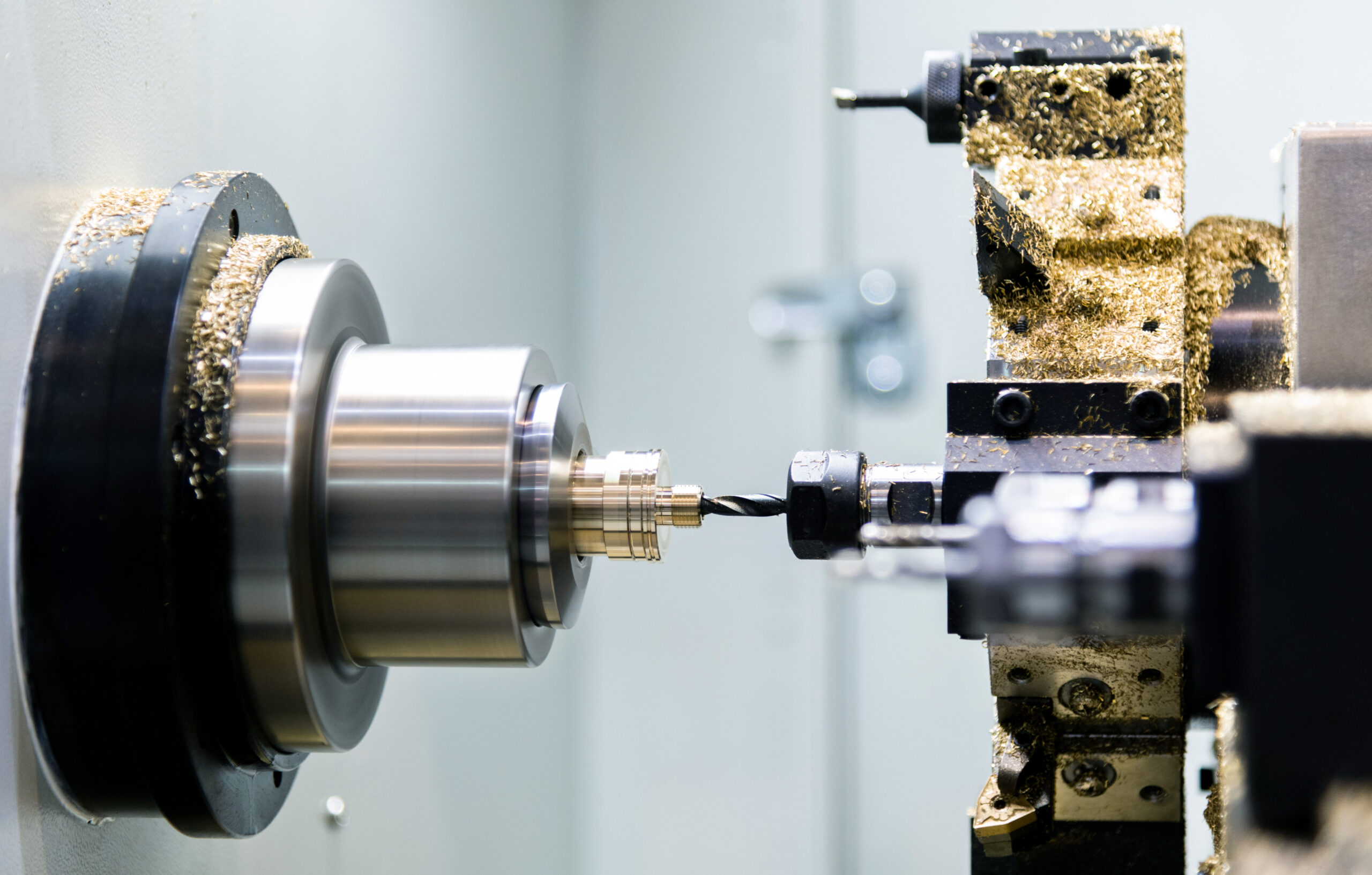

We are your obsolete parts solution provider. Our rapid reverse engineering and production of complex machine components minimizes downtime and keeps equipment running efficiently.

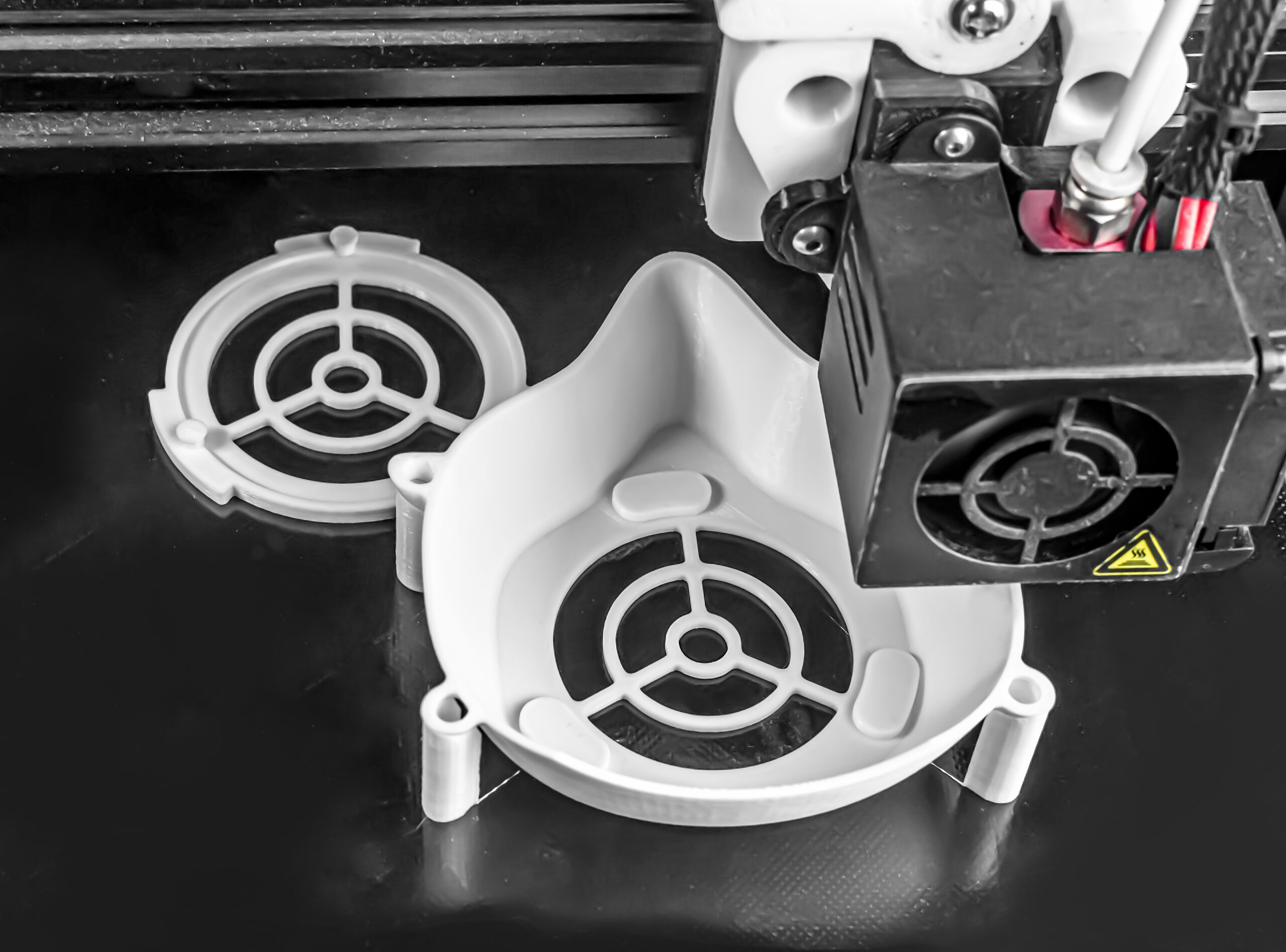

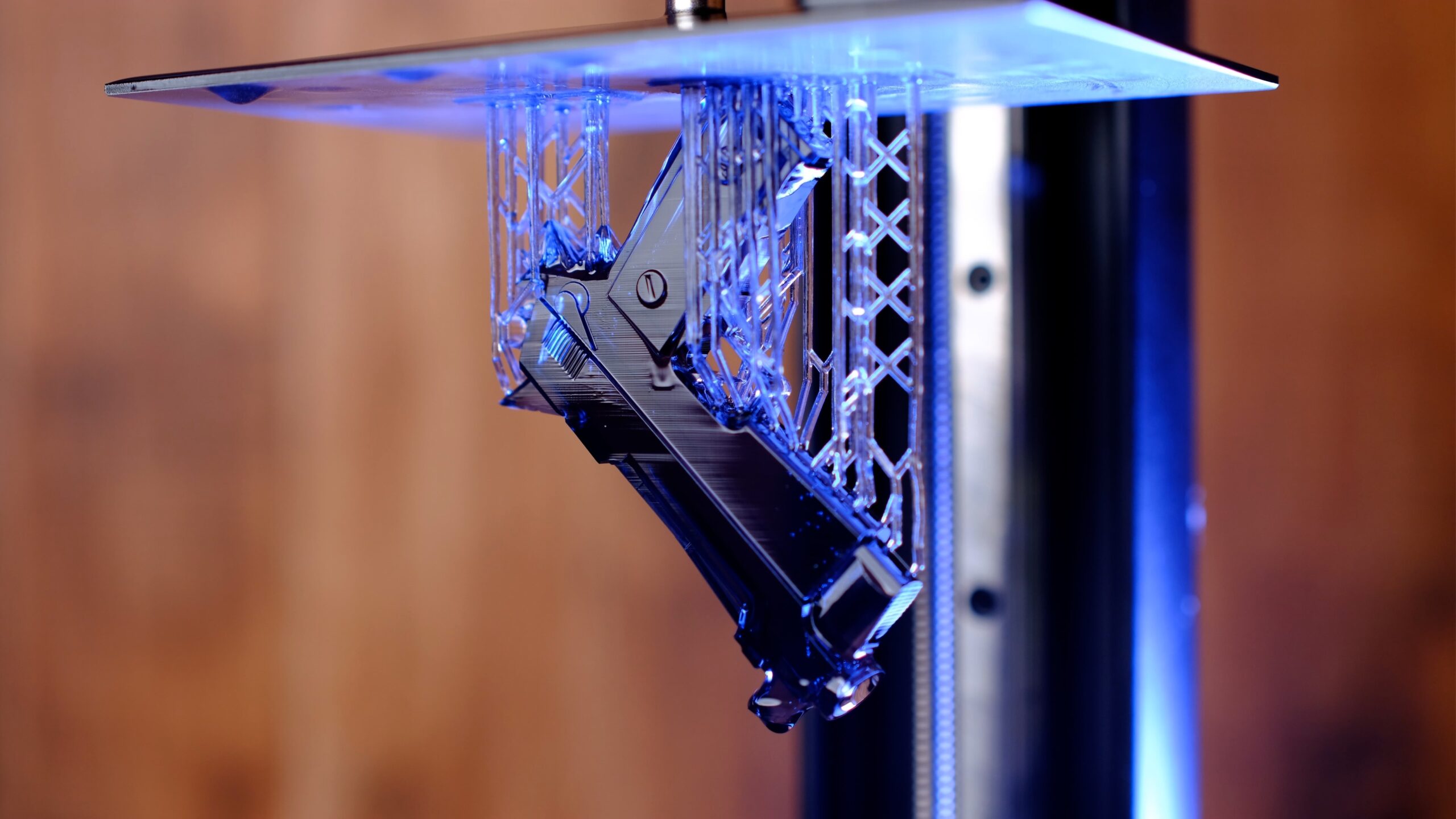

Utilizing on-demand 3D printing, you can lower the cost of custom tooling and maintenance, repair, and operations (MRO) by up to 90% compared to traditional sourcing, support aging equipment, and minimize spare part inventory.

Our USA production facilities enable on-demand production of replacement parts, minimize downtime, and reduce/eliminate dependence on global supply chains.

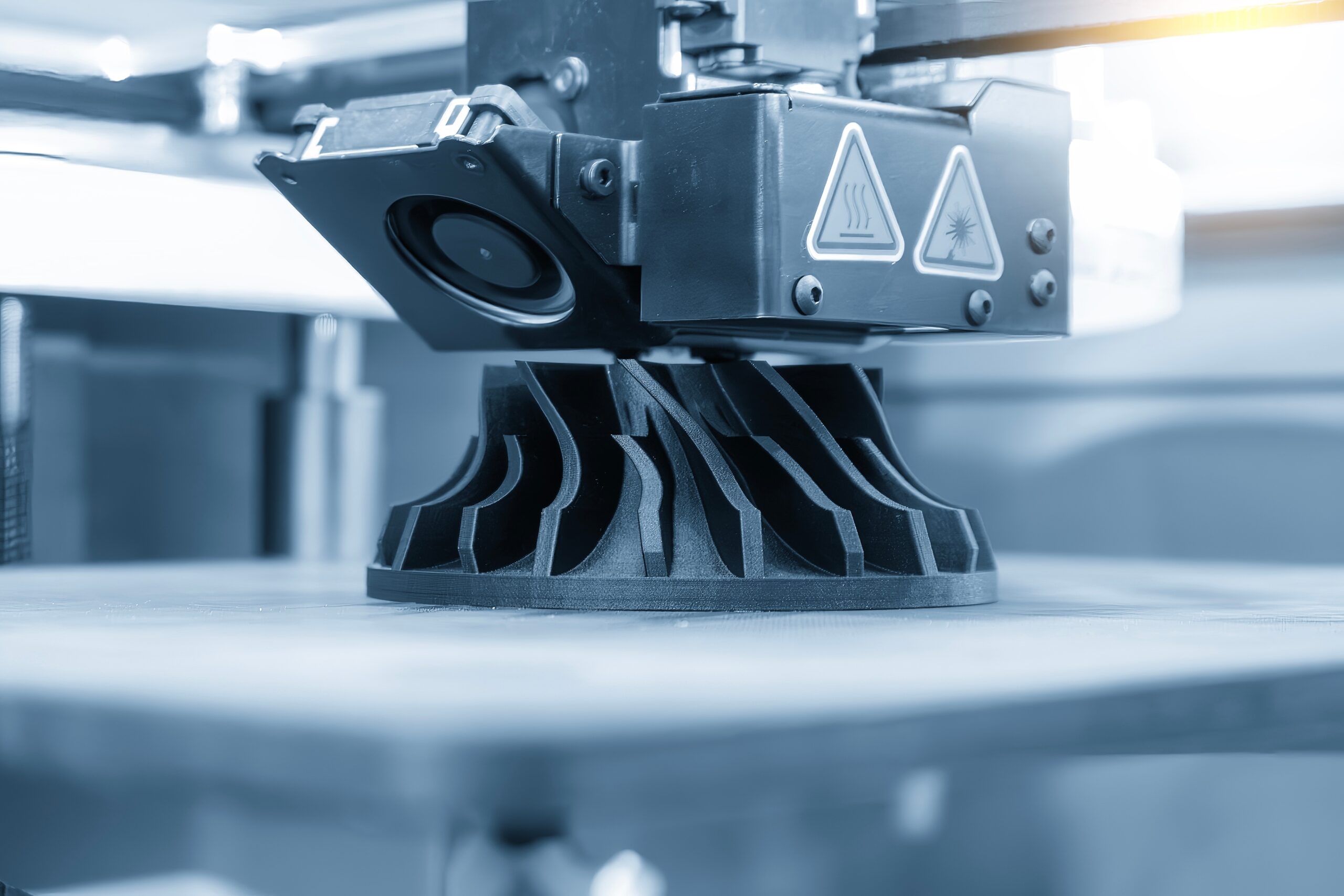

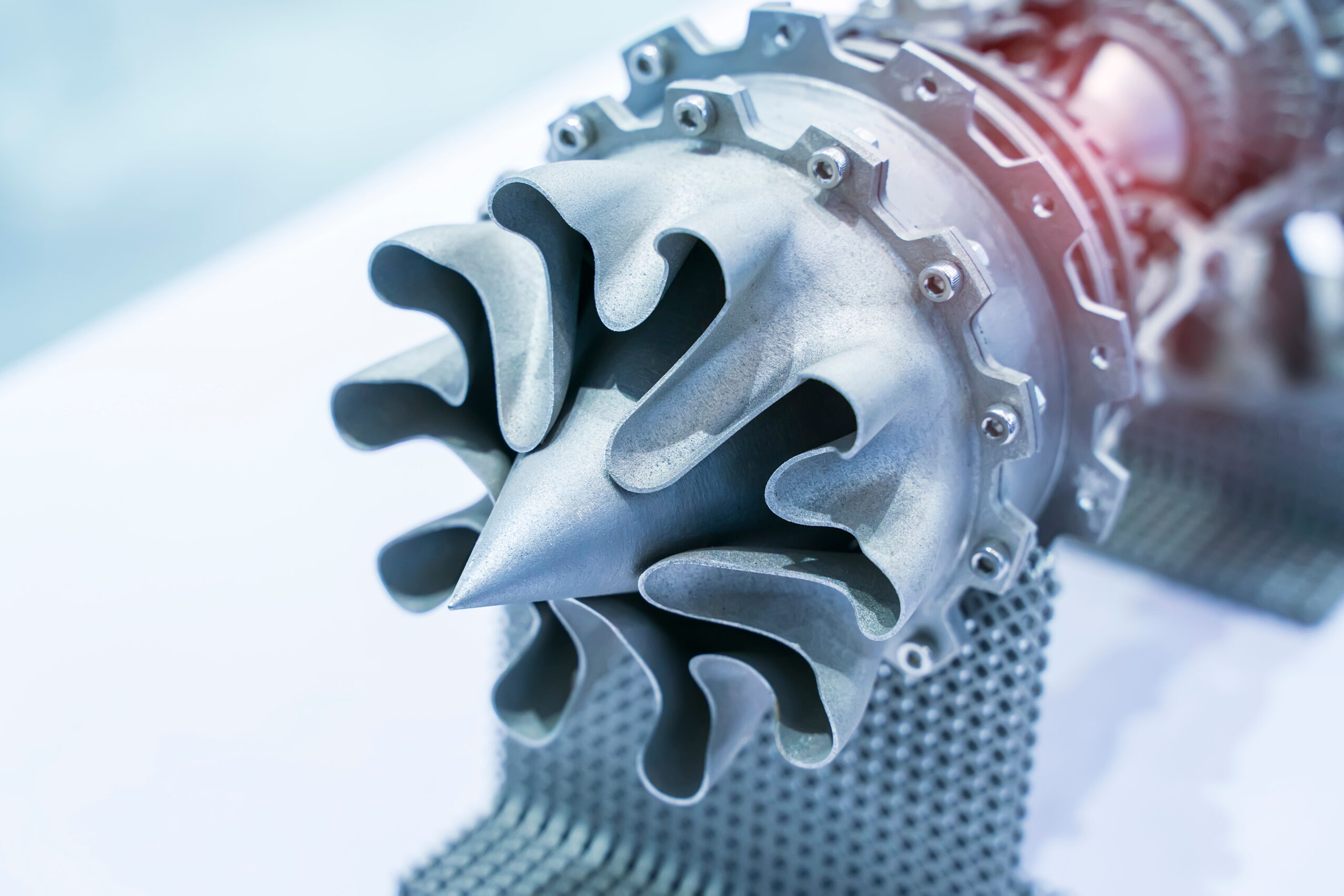

With additive manufacturing, we can create complex geometries that are difficult, if not impossible, to achieve with conventional methods. This can result in lighter, more efficient, and higher-performing equipment.

Utilizing metal 3D printing of production parts, especially stainless steel, supports industry regulations compliance that meet the strict food safety and sanitation standards.

Our 3D printing facilities allow for the rapid development of custom safety guards, ergonomic aids, and other protective devices to address safety hazards and comply with regulatory requirements.

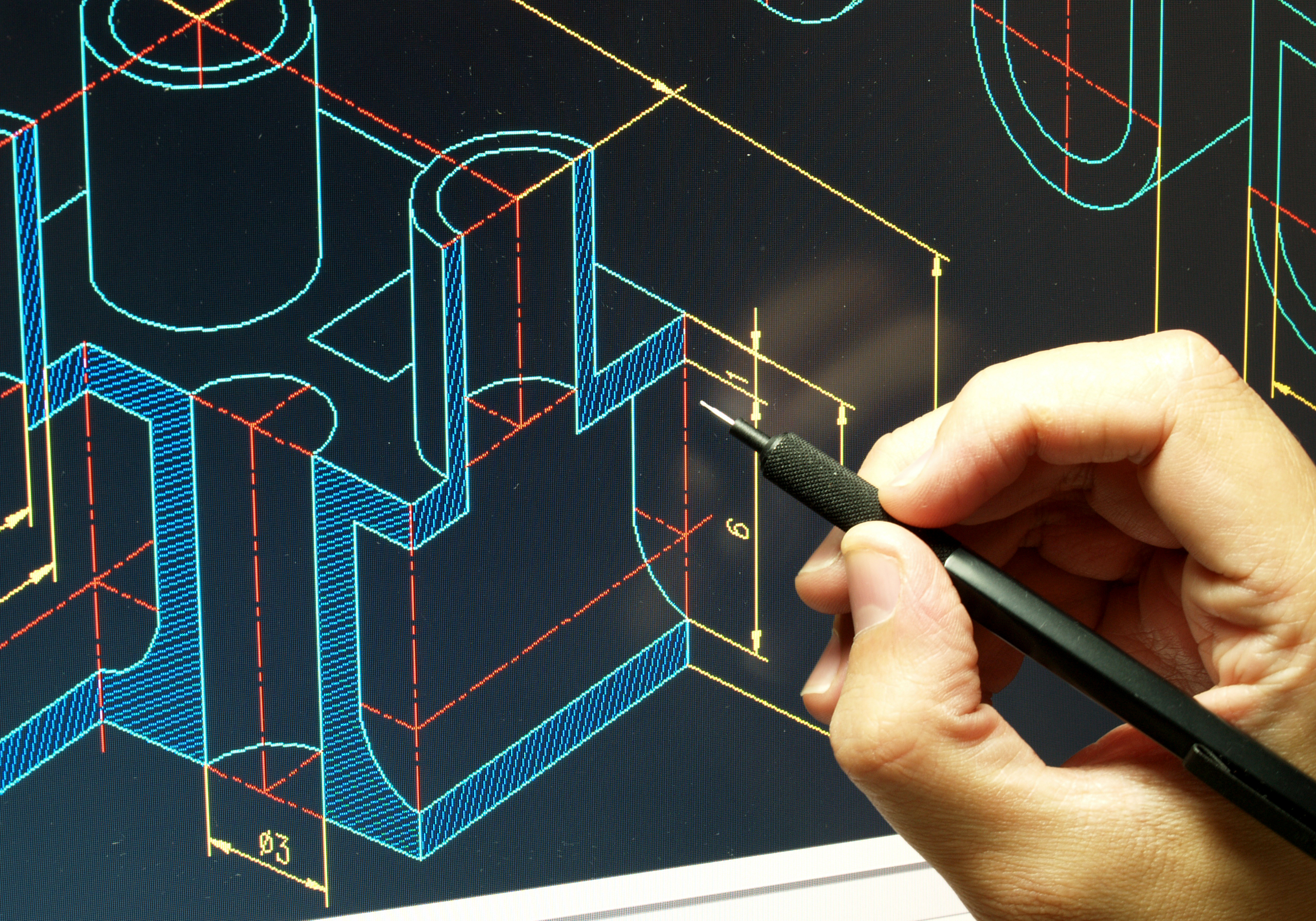

Our engineering teams can collaborate with your teams to rapidly prototype and iterate new designs, fostering innovation and customization to meet specific production needs and new product requirements.

Produce high-quality precision products with short lead times in mission critical environments.

AFORGE AM incorporates a range of innovative techniques such as automation, robotics, additive manufacturing (3D printing), artificial intelligence, internet of things (IoT), and data analytics paired with decades of in-theater experience for fast results at the speed of relevance.

Design / Engineering Services

Advanced Manufacturing

Supportive Manufacturing Processes