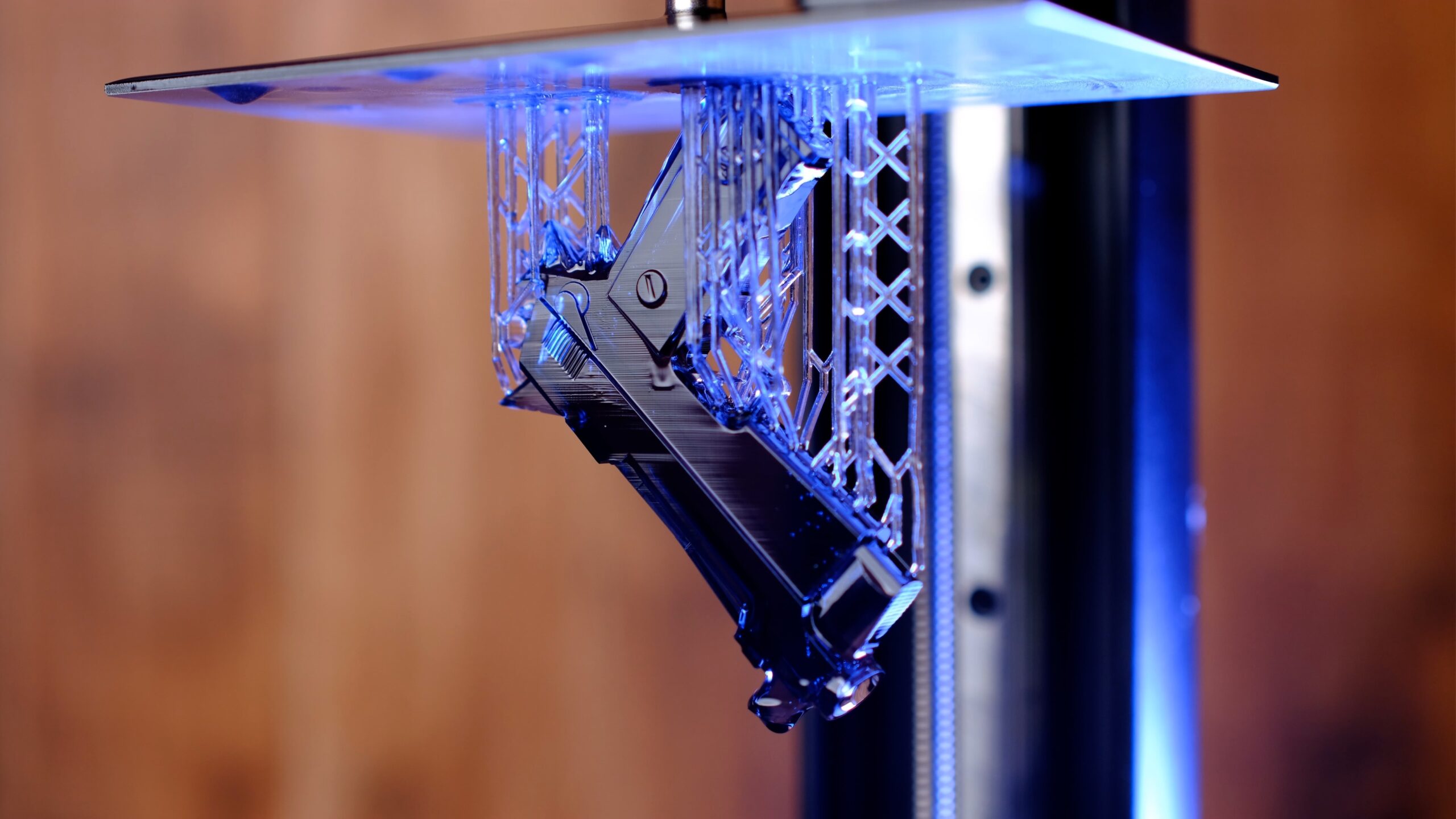

AFORGE combines cutting-edge technologies such as 3-D printing, additive manufacturing, and subtractive manufacturing with comprehensive design, rapid reverse engineering, and prototyping to help you support your clients.

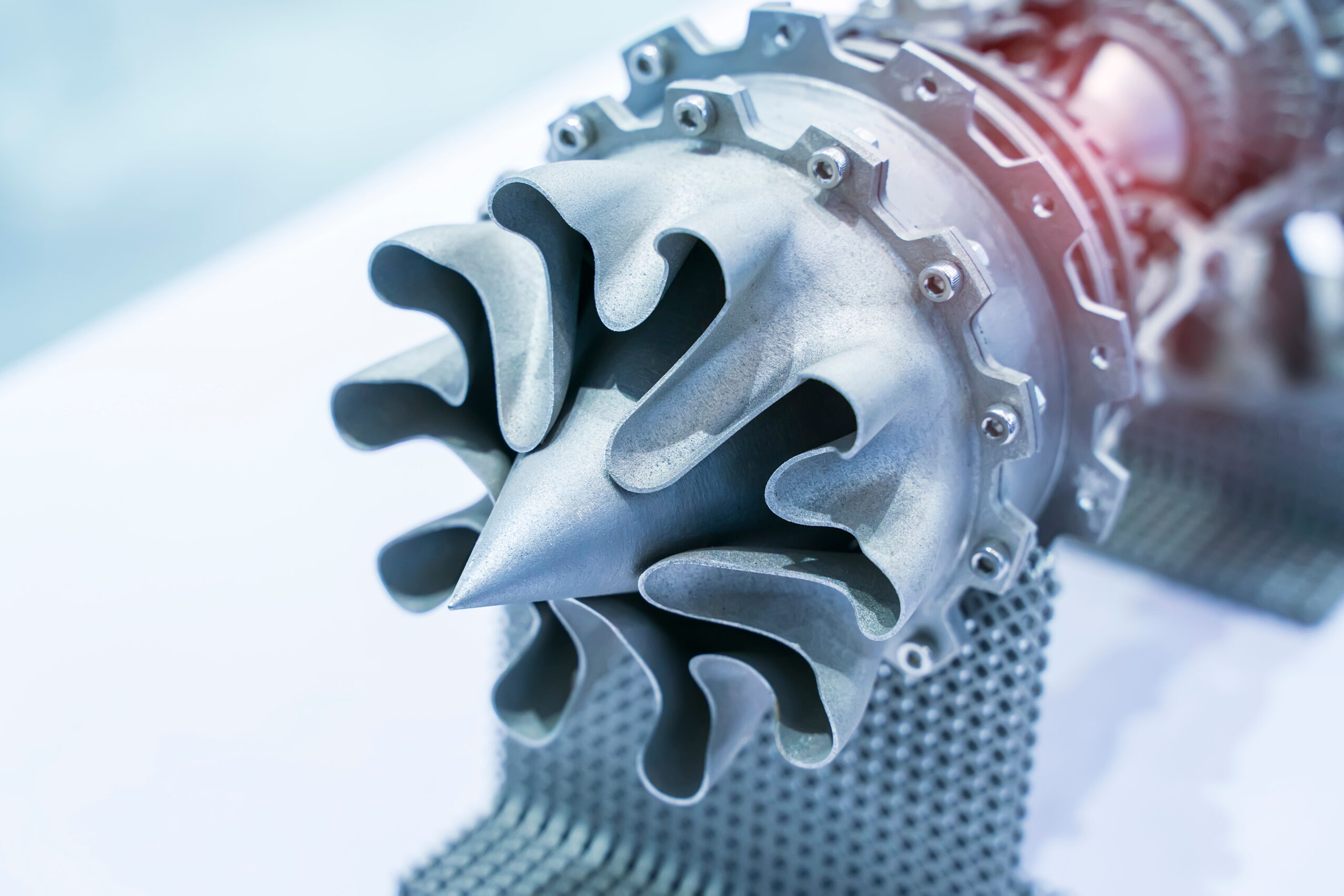

We provide our partner network the ability to fulfill a wider range of customer requests, including intricate geometries, metal and polymer components, and rapid design changes, for single-unit prototypes to scalable, repeatable, and cost-effective production runs.

Automation, digital quoting, rapid reverse engineering, and prototyping technologies reduce production timelines, enabling our partner network to respond to market demands faster and deliver parts more quickly.

AFORGE helps our partner network grow their business by expanding their offerings. Our partners can offer new materials, white-label production, processes, and innovations (lightweighting, integrated assemblies) that may not be available through traditional suppliers.

Engineering and advanced manufacturing reduce labor, material, and inventory costs through automation, digital inventories, and on-demand production. This helps our partner network to offer more competitive pricing and operate with less overhead

AFORGE helps our partner network maintain higher quality standards through our precise, advanced manufacturing processes, which deliver higher quality products consistently, with fewer defects.

Produce high-quality precision products with short lead times in mission critical environments.

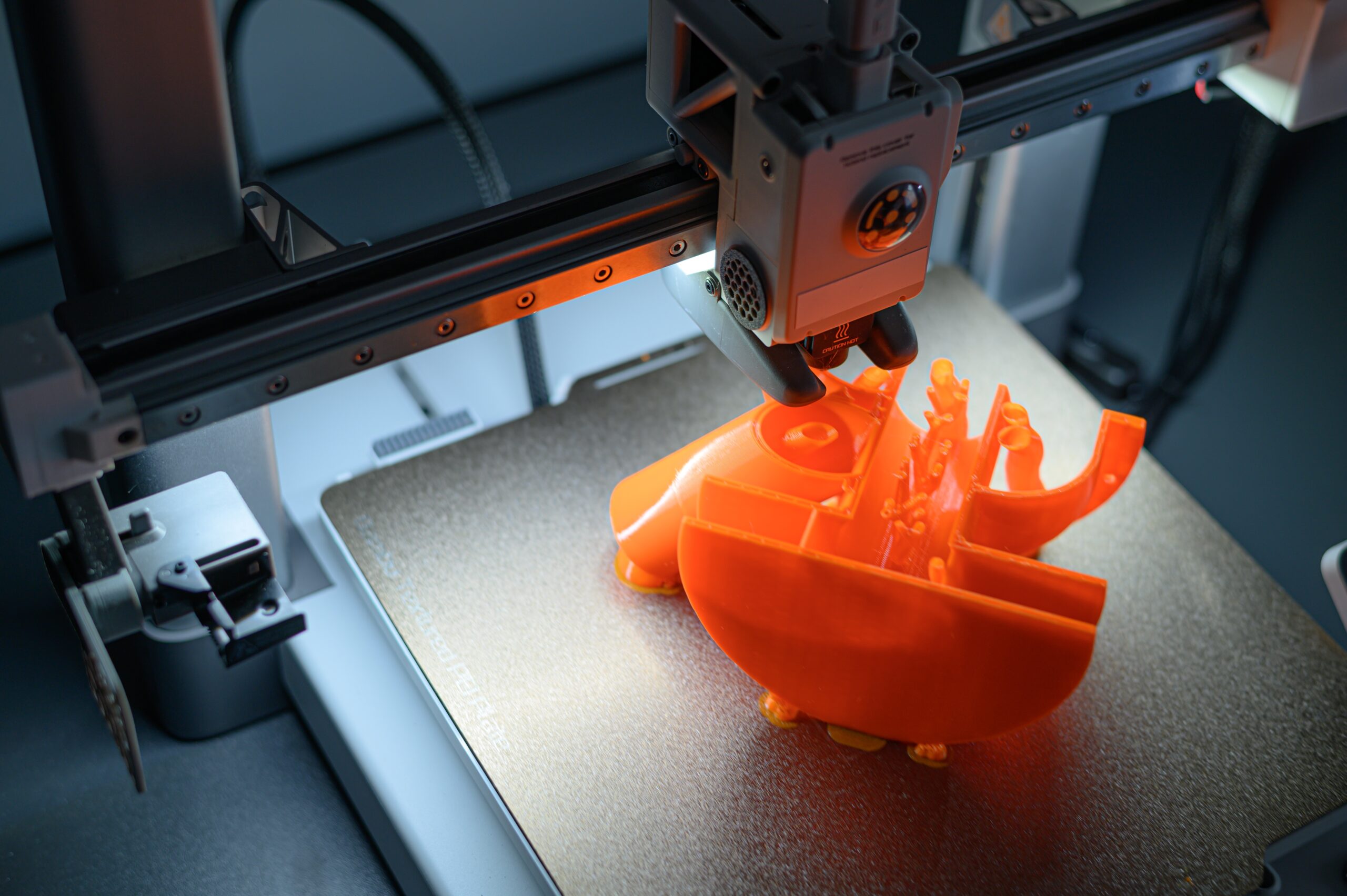

AFORGE AM incorporates a range of innovative techniques such as automation, robotics, additive manufacturing (3D printing), artificial intelligence, internet of things (IoT), and data analytics paired with decades of in-theater experience for fast results at the speed of relevance.

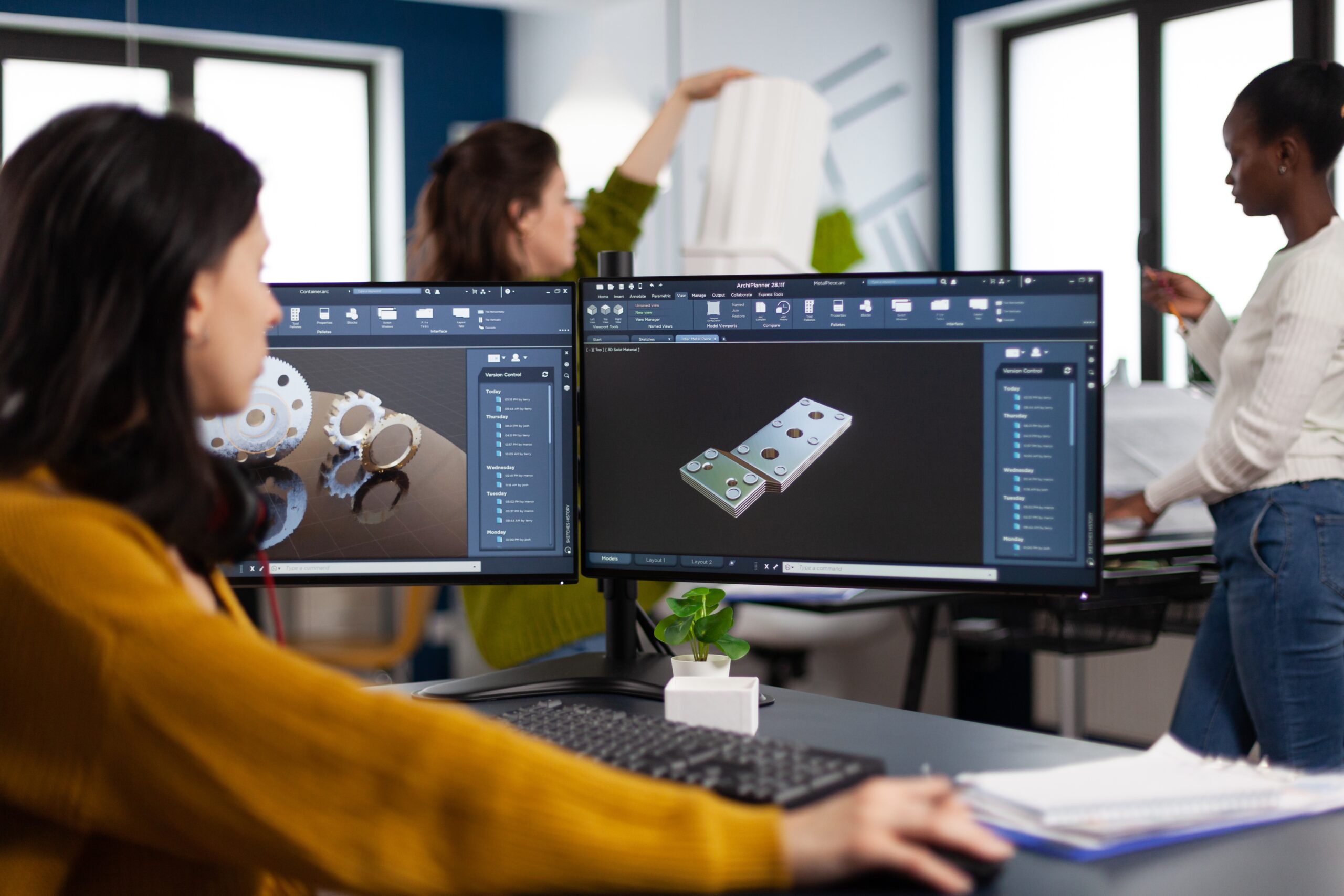

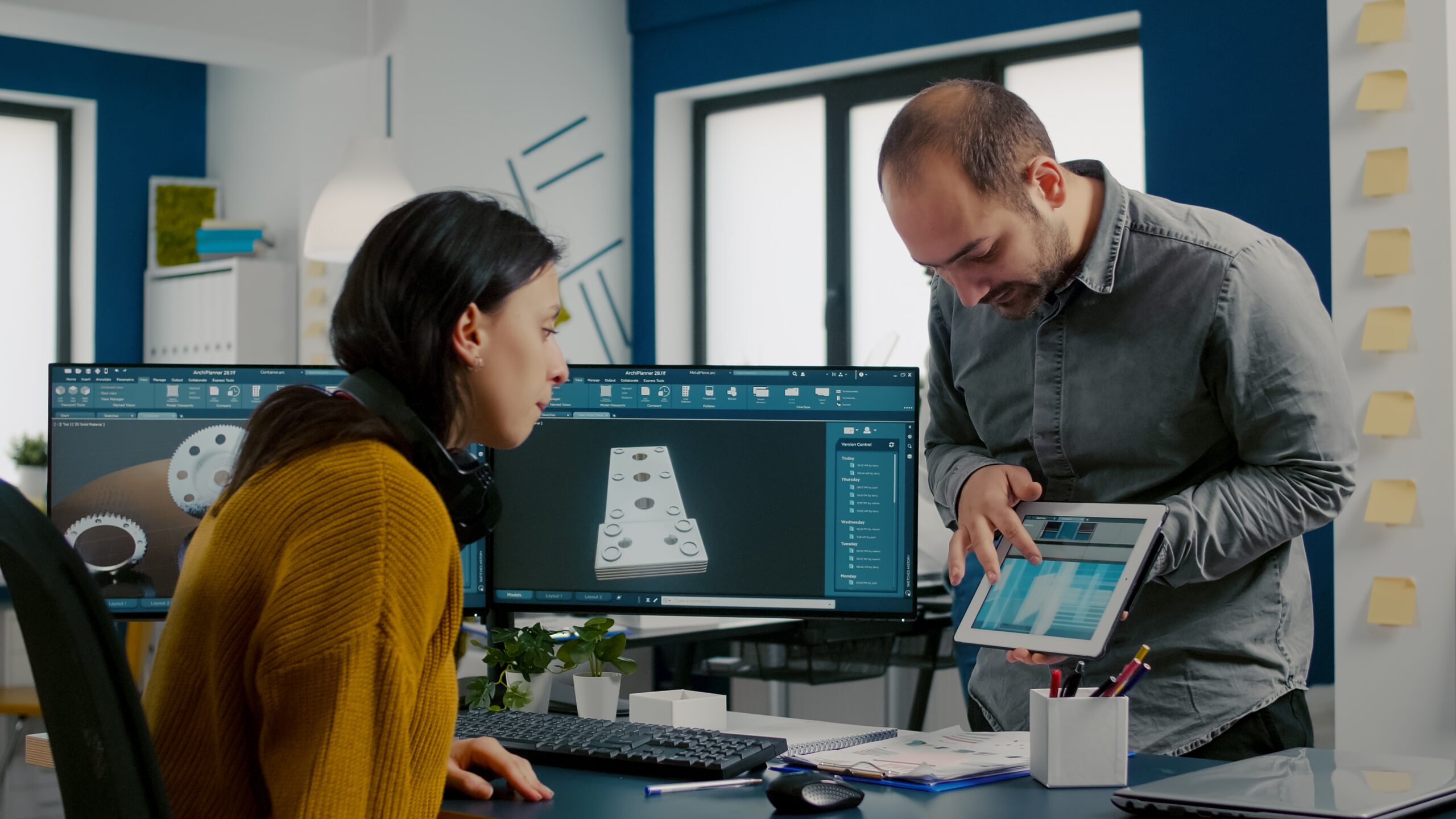

Design / Engineering Services

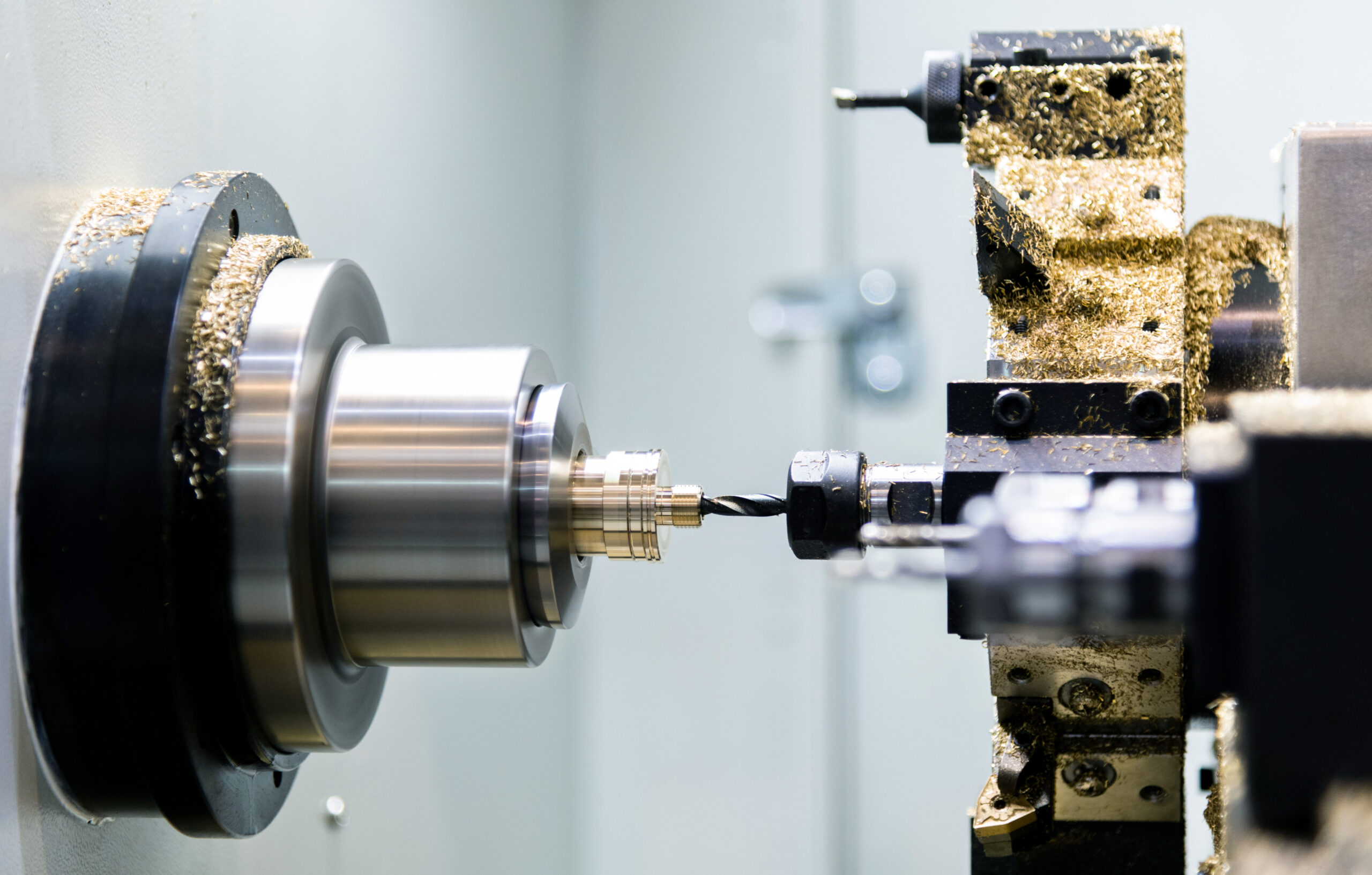

Advanced Manufacturing

Supportive Manufacturing Processes