As vehicles age and OEMs discontinue support, car, motorcycle, and boat owners and parts resellers often struggle to find affordable parts due to limited supply. Through our state-of-the-art technology and advanced materials (metal and polymers), AFORGE’s Engineering and Advanced Manufacturing resolves several critical challenges faced by resellers of obsolete automotive, motorcycle, and boat parts.

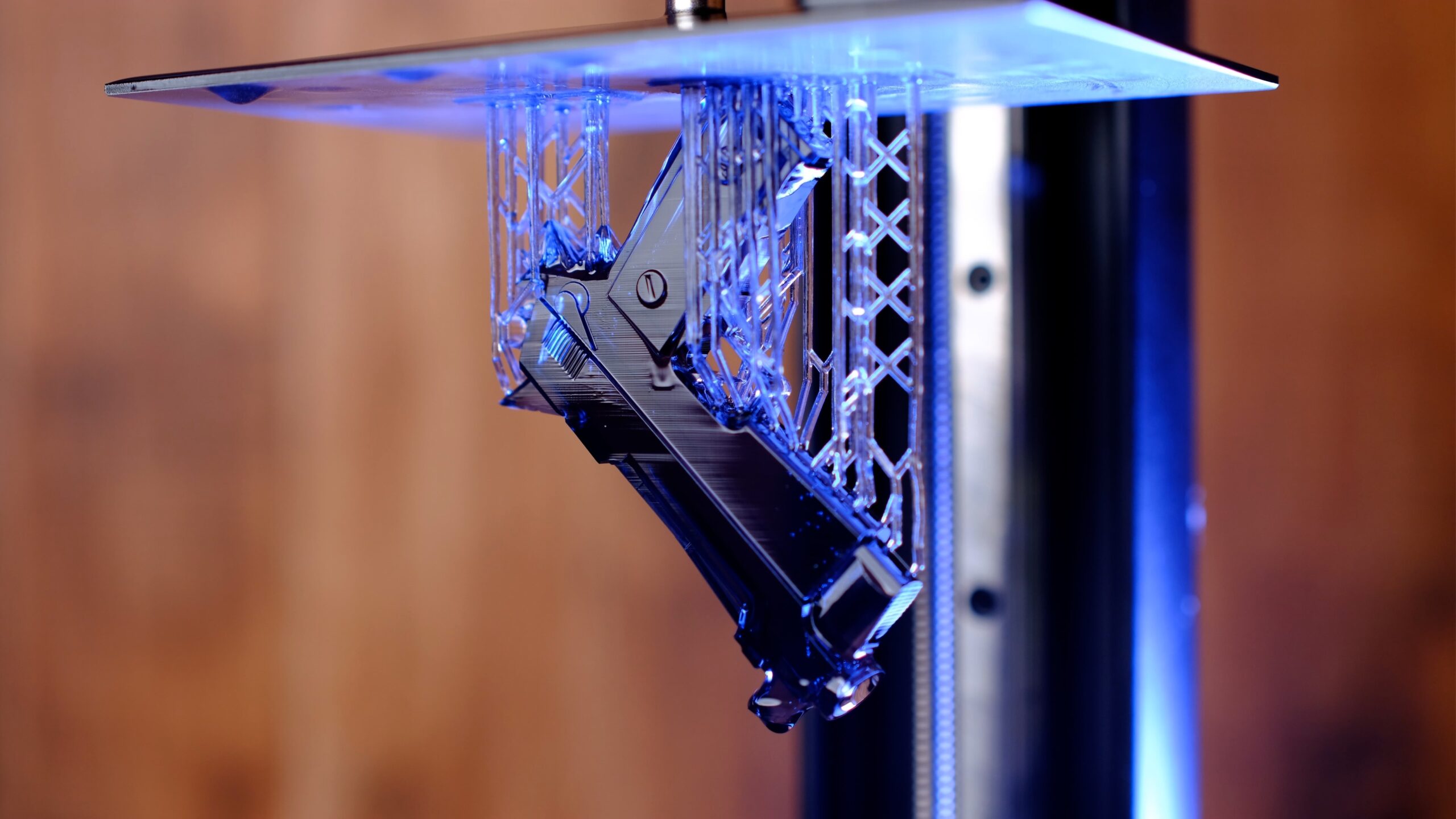

We are your obsolete parts solution provider. Our engineers can recreate legacy parts using 3D scanning and digital modeling even when original tooling or blueprints are unavailable. Our USA production facilities can produce discontinued or low-demand parts on demand, eliminating reliance on diminishing or non-existent OEM inventories.

Our USA production facilities can produce discontinued or low-demand parts on demand, eliminating the reliance on diminishing OEM inventories and global supply chains.

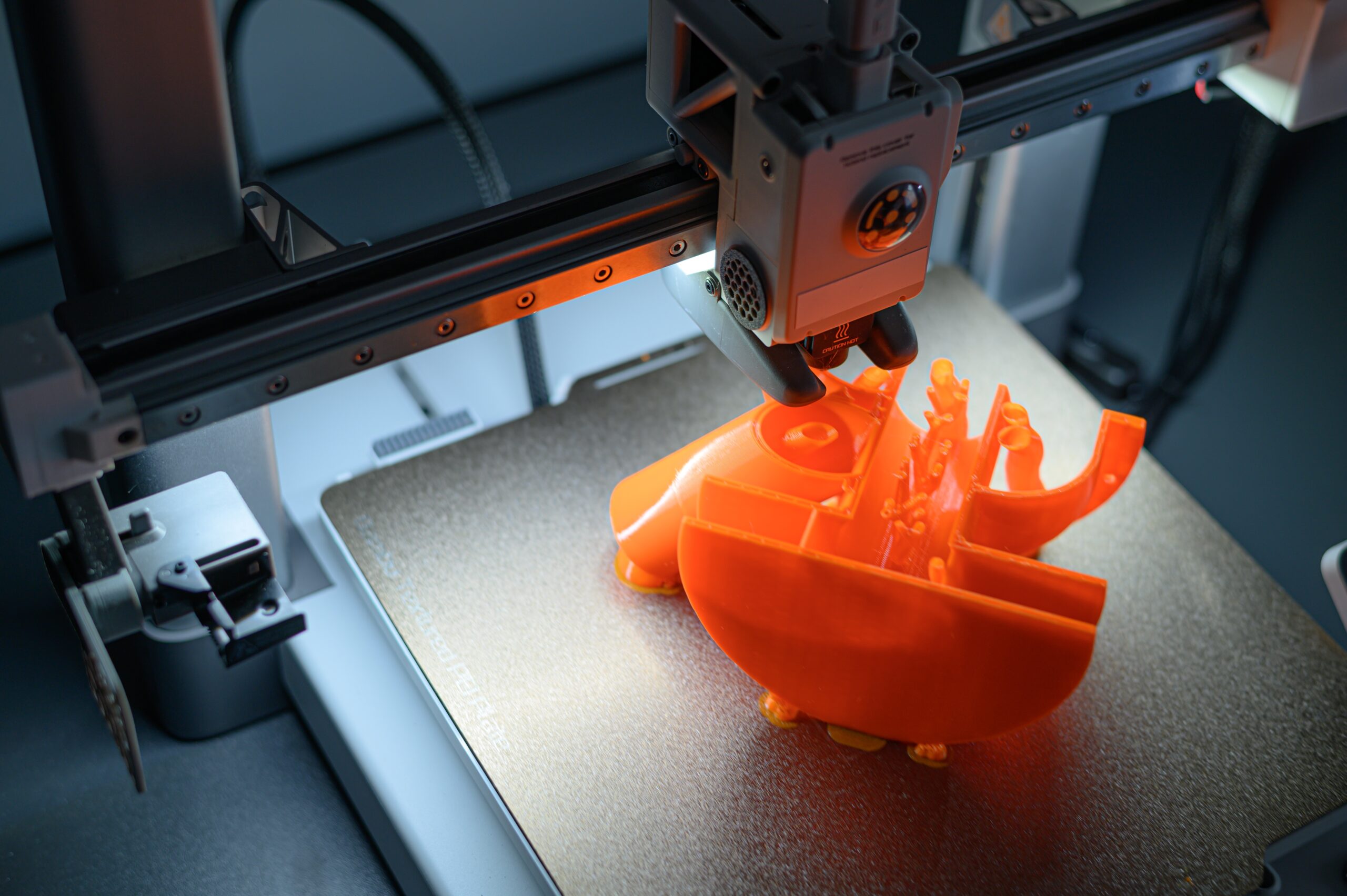

Rapid reverse engineering and advanced manufacturing produce replacement parts quickly, reducing customer wait times compared to traditional remanufacturing methods.

AFORGE helps our clients grow their business by catering to a variety of vehicle enthusiasts. Parts for older and specialty vehicles, not often available through traditional channels, can be produced and sold, opening additional revenue streams.

AFORGE supports our clients in customized runs of single-unit prototypes to scalable, repeatable, cost-effective production runs for niche aftermarket demand.

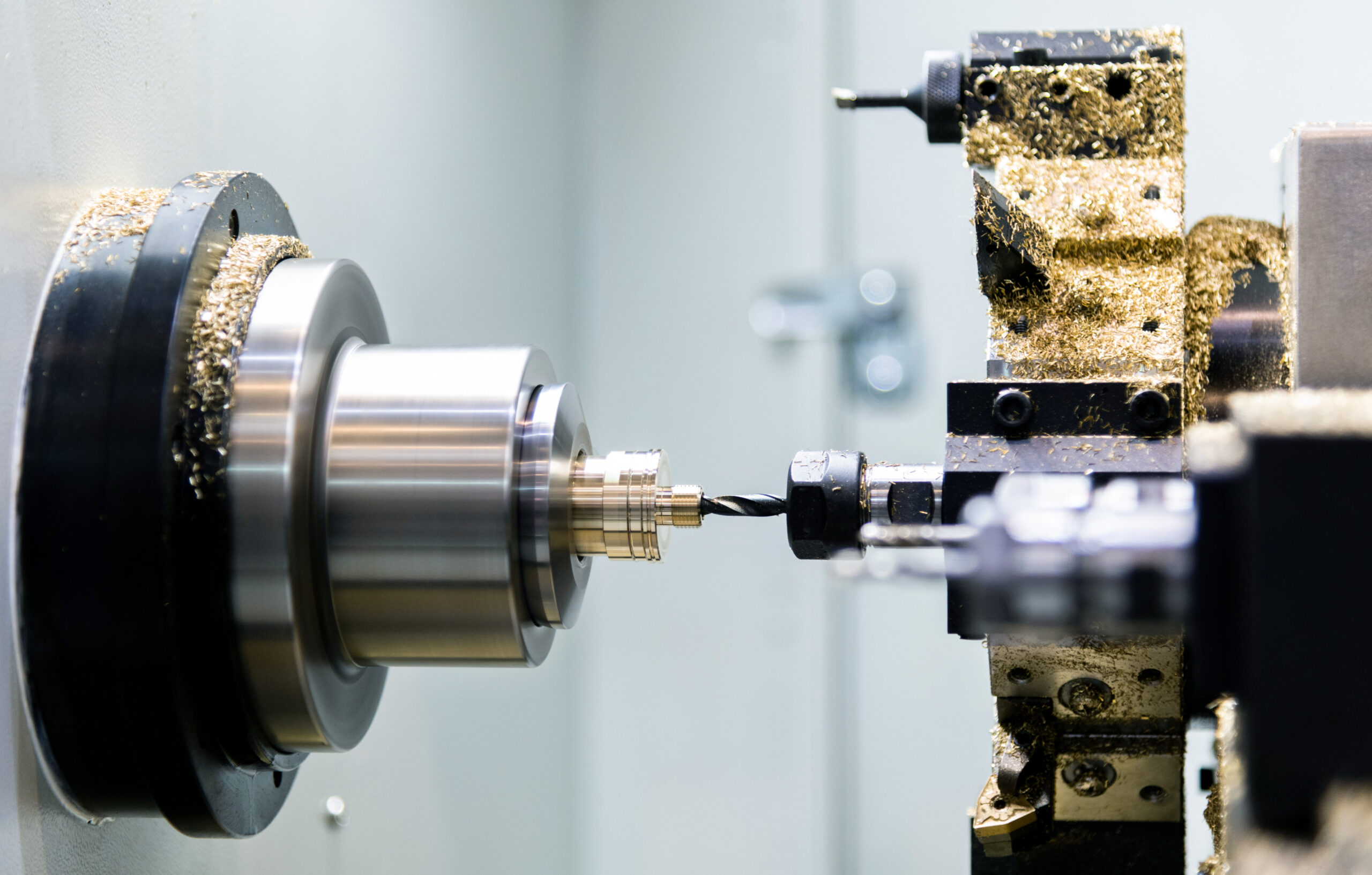

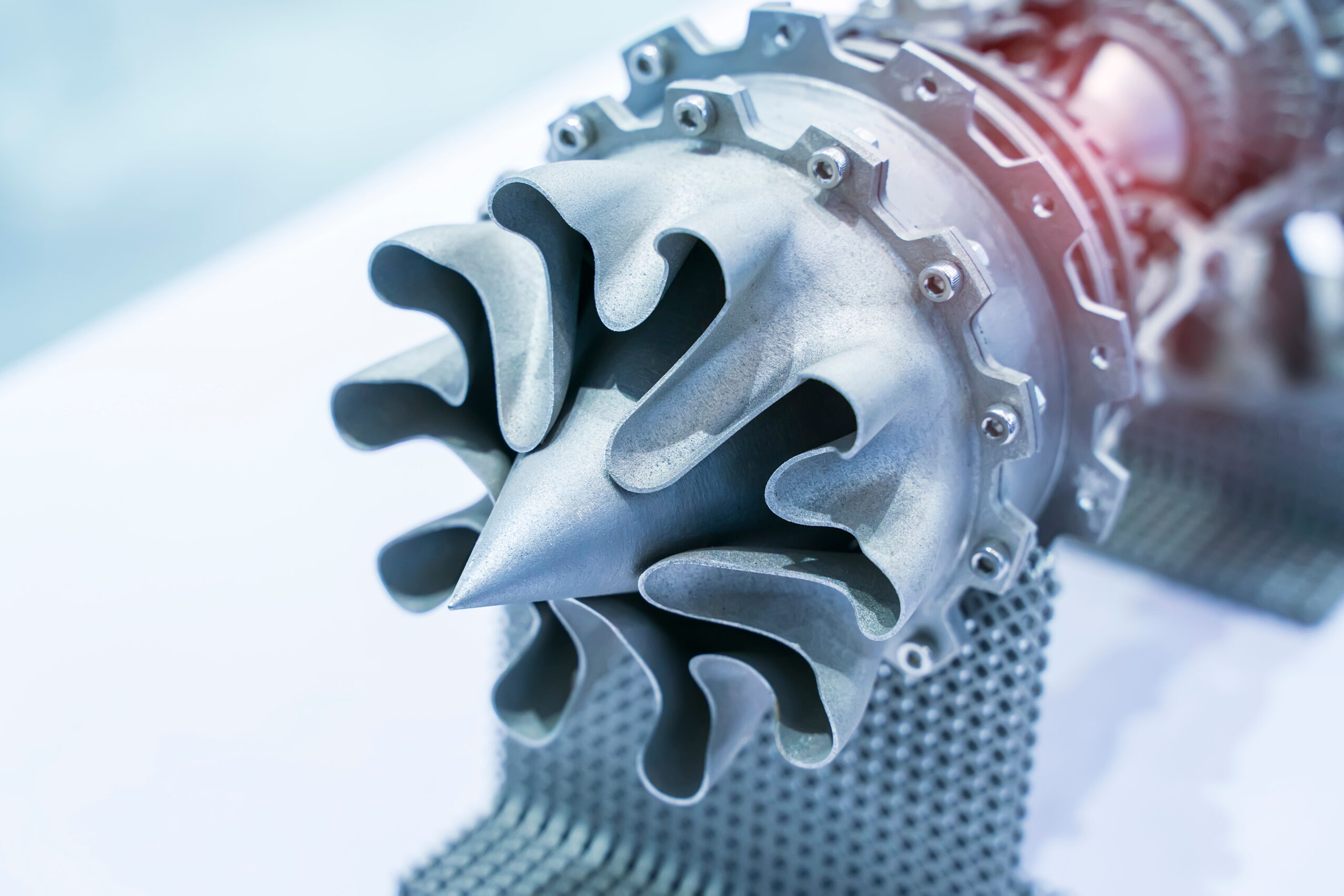

Advanced manufacturing utilizing durable metal components outperforms cast originals, thus

Produce high-quality precision products with short lead times in mission critical environments.

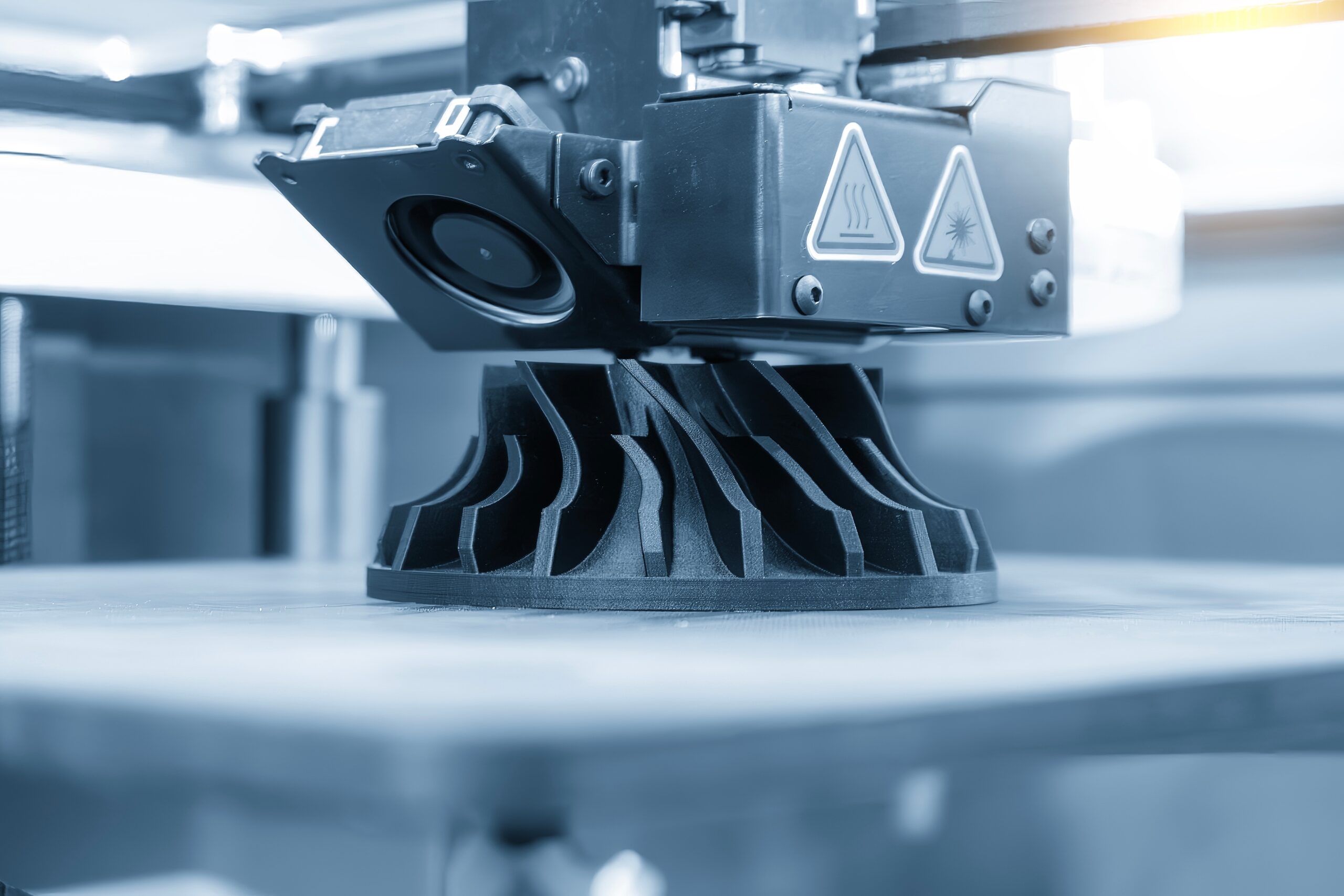

AFORGE AM incorporates a range of innovative techniques such as automation, robotics, additive manufacturing (3D printing), artificial intelligence, internet of things (IoT), and data analytics paired with decades of in-theater experience for fast results at the speed of relevance.

Design / Engineering Services

Advanced Manufacturing

Supportive Manufacturing Processes