Our AFORGE team distinguishes itself through advanced technology integration, deep government and defense expertise, security compliance, and a flexible, customer-centric approach. A few of our key differentiators are:

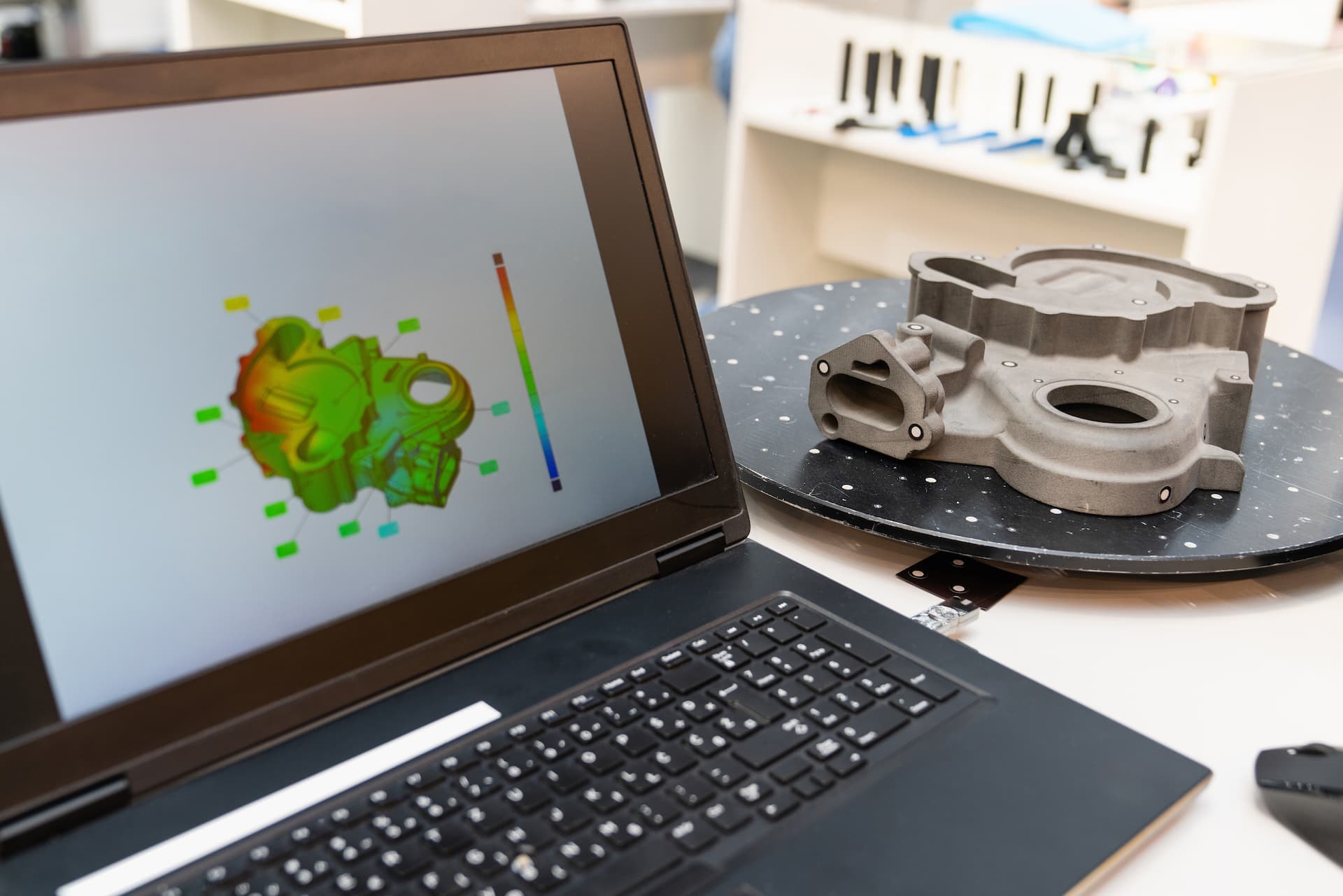

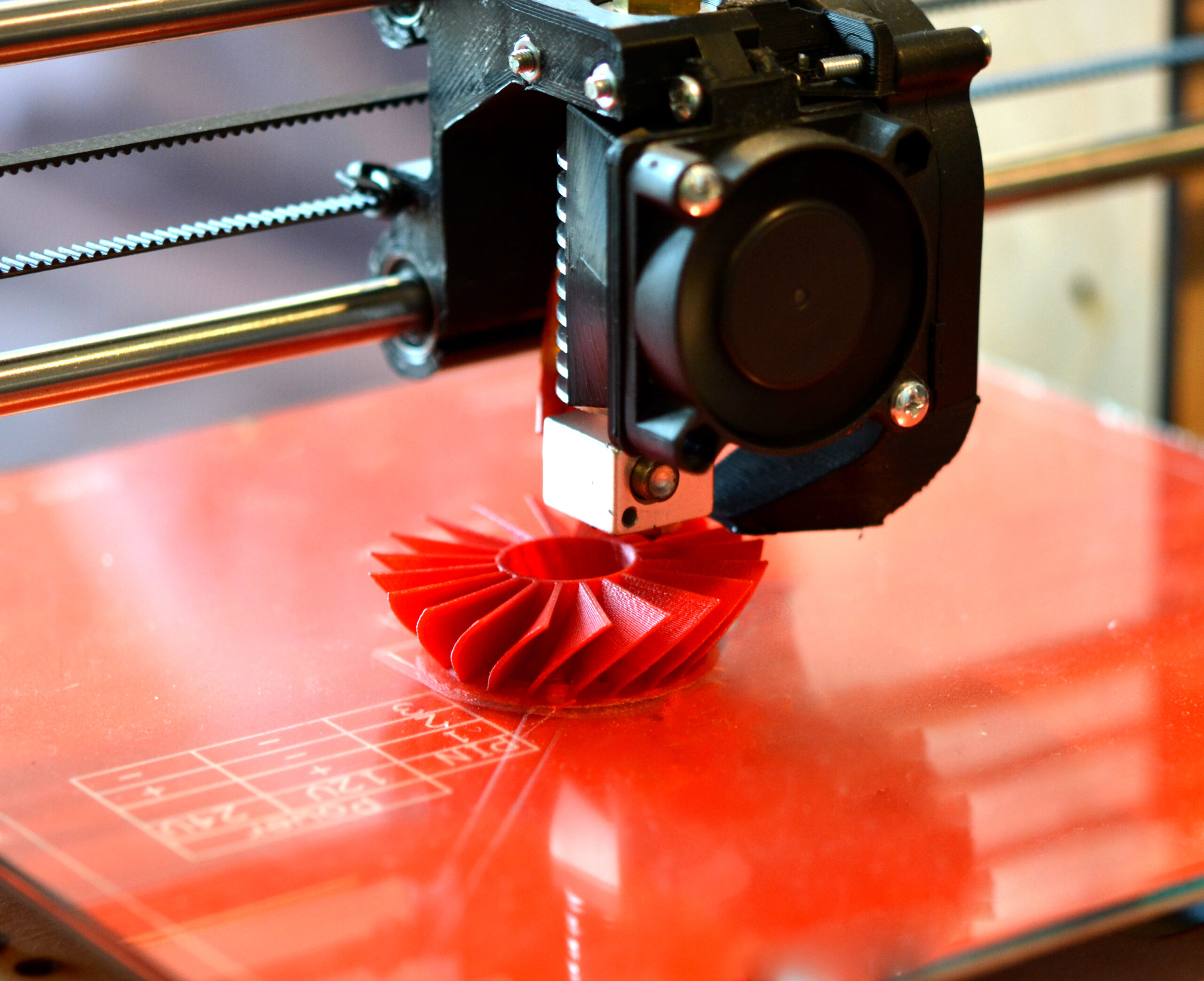

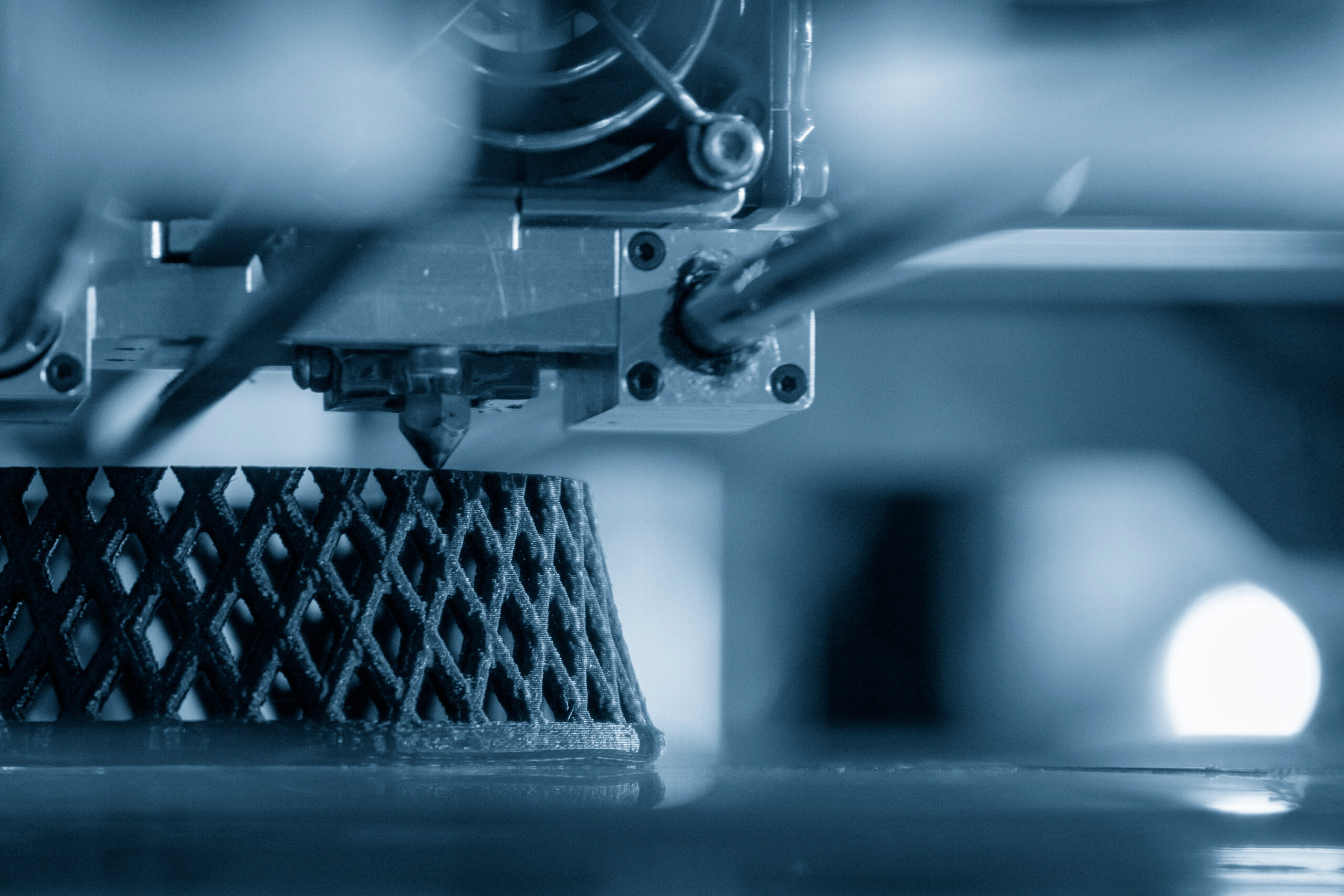

- Hybrid Manufacturing: Additive + Subtractive Integration

- State-of-the-Art Technology

- Reverse Engineering

- End-to-End Engineering Solutions and Flexibility

- Wide Range of Materials

- Customer Collaboration and Support

- Continuous Process Improvement

- Supply Chain Resilience and Scalable Production

- Security, Compliance, and Government Readiness

- Classified Parts Production

- Mission-Focused Culture

- Teaming Partners

- Rapid Capabilities Operations (RCO)